655

Jun 07-2024

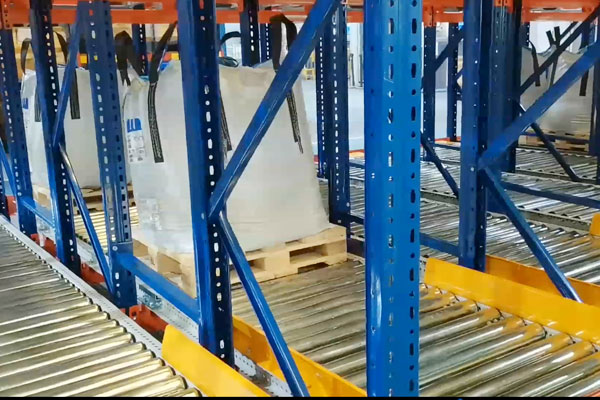

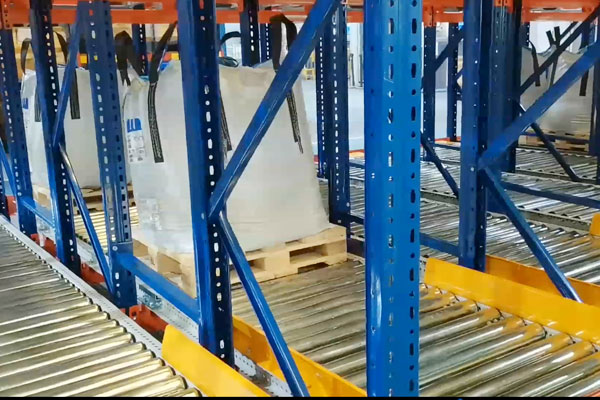

Gravity racking, also known as flow racking or Pallet Live Storage Rack, is a storage system that uses the principle of gravity for loading and retrieving goods. Here are some basic facts about gravity racking:

Working Principle

Gravity racks utilize the weight of goods to allow them to slide along inclined roller tracks or wheels, enabling first-in, first-out (FIFO) storage.

Main Components

Frame: The supporting structure of the system.

- Roller Tracks/Wheel Tracks: Paths for goods to slide, consisting of rollers set at an incline.

- Brake System: Controls the sliding speed to prevent collisions.

- Guides: Ensure correct movement paths.

Benefits

- Increased Efficiency: Goods move automatically to the picking position, reducing handling time.

- High Space Utilization: Compact design maximizes warehouse space.

- FIFO Management: Ideal for perishable goods.

Applications

- Food and Beverage Industry: Adheres to strict FIFO rules.

- Manufacturing: Stores parts and semi-finished products.

- Logistics and Distribution Centers: Enhances picking efficiency and reduces operation time.

Installation Steps

1. Planning and Design: Design the layout based on warehouse space and goods type.

2. Frame Assembly: Construct the basic structure.

3. Roller Installation: Fix roller tracks or wheels at the appropriate incline.

4. Brake System Setup: Install and adjust brakes to control sliding speed.

5. Testing and Adjustment: Conduct trial runs, check performance, and make necessary adjustments.

Maintenance

- Regularly check for wear on rollers and tracks, and replace damaged parts.

- Ensure frame and connections are secure to avoid safety hazards.

- Keep the tracks clean of dust and debris to maintain smooth operation.

This comprehensive understanding of

gravity racking can help in optimizing warehouse management and boosting overall efficiency.

For further information about Sale Prices and Detail Spesification Racking in Aceally, or others product from ACEALLY, leave us a message(

[email protected]) and our marketing will be happy to contact you soon, thanks.

Prev

Next

+86 13959222269

+86 13959222269 [email protected]

[email protected]

+86 13959222269

+86 13959222269 [email protected]

[email protected]